RAKtherm Piping Systems Technologies

RAKtherm’s product portfolio of wide range of integrated piping systems is responsible for delivering technological developments and the research & development that leads to innovative pipe systems to build the most iconic projects in the world.

Our commitment to plastic conversion technology and innovation continues to be the core of our quality management systems. As the construction engineering become more complex and more technically demanding, our engineering expertise will be the pillar to the advancement of the MEP industry.

1. PPR Piping Systems

We are have carefully blended and formulated our own PP-R resins (polypropylene-random) which guarantee that we are only using the highest quality of PP-R granules in our piping systems. A random copolymer grade of PP-R was specially developed for engineering applications with certain stringent requirements.

The random combination of short and long hydrocarbon chains gives rigidity and flexibility resulting higher resistance to external damage for superior physical properties. Compression strength, elasticity, anti-corrosive and heat resistance properties are the factors which make it suitable for potable hot and cold water applications.

RAKtherm PPR systems are extensively used in food and medical industries owing to its harmless and safe properties. Proven to be non-toxic and stable chemically even at elevated temperatures.

RAKtherm PPR piping systems is manufactured in conformance to DIN 8077/8078 German standard.

PPR is the Perfect Solution

In accordance with its areas of application, RAKtherm piping systems is designed for continuous temperatures of 0°C to 90°C, and short-term peak temperatures of up to 100°C with a service life of 50 years. Therefore, RAKtherm is the perfect solution for all types of chilled and heating water networks.

RAKtherm PPR pipes is also very light in weight which is a big advantage for installation and handling and its fusion welding guarantees perfect seal therefore prevents leakage. Chemical components of PPR plastic pipe materials prevent from any bacterial growth which makes RAKtherm highly hygienic and non-toxic.

RAKtherm, a Healthy Choice and Environment Friendly

We believe that health is wealth; we never compromise the safety of our products. At RAKtherm, we produce products that are safe and harmless both for human’s health and environment.

PP-R is a material with excellent chemical resistance which does not react to most chemicals, with non-corrosive properties, proven to be physiologically and microbiologically harmless making it suitable for hot and cold water applications. All materials used in piping systems are 100% recyclable which can be used again in other plastic products, no nickels and chrome which can be found in metal fittings.

2. MULTI-LAYER REINFORCED PVC-U PIPING SYSTEMS

● PVC-U REINFORCED PIPES AND FITTINGS ENHANCED SYSTEM (White)

Underground/Aboveground (Solvent Joint)

The enhanced systems with high corrosion resistance properties that is perfect for underground and aboveground piping installations.

● PVC-U REINFORCED PIPES AND FITTINGS INTENSIFED SYSTEM (Gray)

Aboveground (Solvent Joint)

Engineered solution and easy to work on by easing jointing technique using the solvent-cement specifically manufactured by RAKtherm to complement the complete gray systems which creates a highly-reliable piping networks.

● PVC-U REINFORCED PIPES AND FITTINGS INTENSIFED SYSTEM (Gray)

Aboveground (Push-fit)

The intensified PVC-U system of RAKtherm with exceptional multi-layer reinforced rubber joint, that can withstand up to 70°C. This system can significantly provide seamless water tight connection for leak-proof service.

● PVC-U REINFORCED PIPES AND FITTINGS HEIGHTENED SYSTEM (Terracotta Orange)

Underground (Solvent joint)

Engineered solution and easy to work on by easing jointing technique using the solvent-cement specifically manufactured by RAKtherm to complement the complete orange systems which creates a highly-reliable piping networks.

● PVC-U REINFORCED PIPES AND FITTINGS HEIGHTENED SYSTEM (Terracotta Orange)

Underground (Push-fit)

The intensified PVC-U system of RAKtherm with exceptional multi-layer reinforced rubber joint, that can withstand up to 70°C. This system can significantly provide seamless water tight connection for leak-proof service.

WHY RAKTHERM DWV (Drain, Waste, Vent) SYSTEMS?

Because the RNP Technology in RAKtherm’s Multi-Layer Reinforced PVC-U brings technological breakthrough in the piping industry!

RAKtherm is the very first manufacturer to unveil the secret of the new groundbreaking RNP Technology!

DWV Systems (Drain, sewerage, waste, and vent) is the latest development of RAKtherm. A state of the art three-layers-pipe with solid-wall-construction, made from the new generation premium materials which significantly improves its’ durability compared to the conventional pipes.

● RAKtherm’s Groundbreaking RNP Technology

The pipes’ uniform middle-layer-construction is based on special cells to ensure increased in mechanical properties, wherein the inner-layer and outer-layer are combined forming like a ‘sandwich construction’ which results to exceed the requirement for noise reduction, durability, flexibility, and longer-service-life.

● The Rarefied Concept for Noise-Reduction Technology of RAKtherm

RAKtherm launches the newest range of PVC-U piping systems featuring its Noise-Reduction Technology. Noise management is one of the crucial aspects in the interior design of buildings. As the construction technology becomes more complex and more technically demanding, our proficiency in pipe engineering can address to resolve the increasing demand for customers’ guidelines related to well-being.

The pipes are made in multi-layer PVC-U for Sound Attenuation System technically designed for environmental noise control applications. RAKtherm meets the EN 14366 and German standard DIN 4109, confirming its high-efficiency in noise reduction in sewage systems.

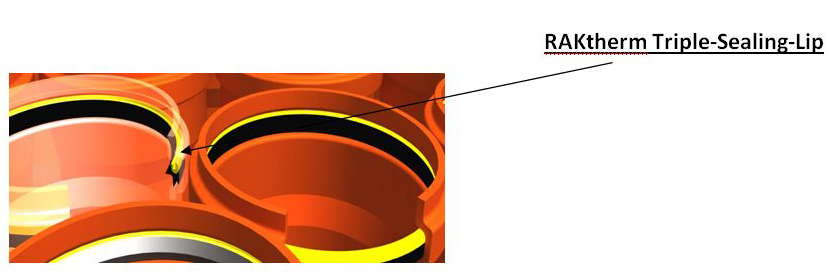

● RAKtherm’s Triple-Sealing-Lip Solutions, Engineered Perfection for PVC Sewer Pipe Systems

The multi-layer reinforced rubber joint, is an integrated seal for plastic pipe systems for aboveground and underground applications of drainage sewerage systems.

RAKtherm’s triple-sealing-lip solutions is now the industry-beating performance, it is highly effective seal which requires low-jointing force while ensuring a secure seal across wide range of pipe-joint level tolerances.

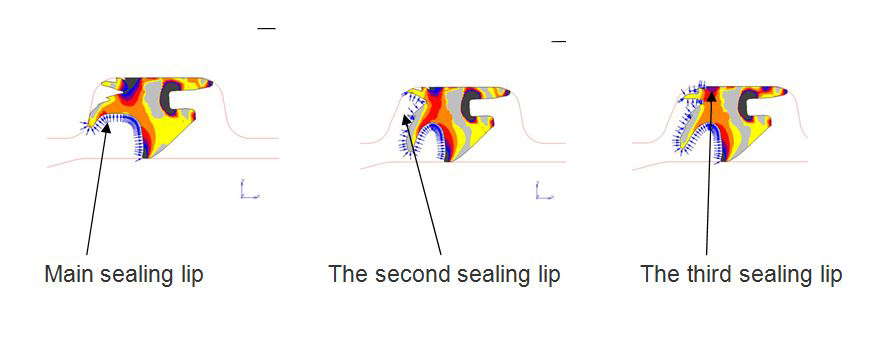

The Concept of Triple-Sealing-Lip from RAKtherm

DIN lock™ is a combined lip and compression seal that is positioned in the socket by the pipe manufacturer. The seal is designed to absorb any permissible variation in the groove.

● Geometric Design for Functionality

The unique design has a flexible thermoplastic elastomeric sealing element bonded to a polypropylene retaining ring which holds the seal firmly in the correct position during pipe transportation and joint assembly.

RAKtherm triple-sealing-lip seal is designed to have a low assembly force in minimum gap and on maximum gap, which is able to have a good compression on its 3 different lips. The assembly can be done at maximum compression without any problem.

3. PEX Piping Systems

PEX refers to cross linked polyethylene (PE-X). It is a polymeric material formed by the chemical joining of individual polyethylene molecules in a process called “crosslinking”, because cross linking alters the performance of the original polyethylene polymer improving its’ properties. The primary reason for cross linking the polyethylene (PE) is to increase the physical properties and materials’ elevated temperature performance under load.

This results in a structure that does not soften when high temperature is applied, thus raising the thermal stability of the material under load, which greatly increases the environmental stress crack resistance, resistance to slow crack growth due to deterioration of the material under continuous temperature use, chemical resistance, toughness and abrasion resistance.

The Molecule Structure of Polyethylene and Cross linked Polyethylene

4. Anti-UV Piping Systems

Integrated with anti-UV Technology, Engineered for Higher Level of Piping Solutions

RAKtherm UV systems are integrated with special black anti-UV technology for higher resistance against UV rays intended for outdoor applications under direct sunlight. It is the safest and longest lasting piping solution for outside installation. The revolutionary black anti-UV component reduces expansion and contraction proven to be mechanically stable even under extreme temperatures of 5°C to 95°C at a service life of 50 years.

The creation of RAKtherm anti-UV fittings came up to provide a complete line up of piping solutions excellent for outdoor installations. RAKtherm is noted as one of the very first manufacturer of anti-UV fittings that has been registered in SKZ affirming it’s conformance to the highest standard of quality. RAKtherm being the leader and innovator, will now complete and represent the entire selection of anti-UV piping systems in the market; this will administer a full network of anti-UV pipeline solution under direct and exposed applications.

5. Reinforced Piping Systems

● RAKtherm Reinforced Stabi (RRS System)

The main function is to stabilize the pipes to preserve its quality. RAKtherm Reinforced Stabi Pipes are manufactured from special component of PPR material reinforced with aluminum layer for reduced linear expansion similar to metal pipes for greater strength and better heat resistance. Highly efficient with smooth interior walls that reduces the head loss for increased higher flow rates.

The inner part is covered with aluminum; outer layer is coated with anti-creep layer; the outer layer is coated with PPR as mechanical protection, combined with hot-melt glue between the layers. All these provide better anti-creep properties, greater strength, better shock resistance, and good stability. It can be easily detected with metal detector even when buried under ground. With proven high resilience performance even at the most extreme conditions, making it suitable for hot and cold water applications in residential, commercial, and industrial facilities.

● RAKtherm Reinforced Stabi with UV Protection (RRSV System)

RAKtherm’s Reinforced Stabi UV Pipes are enhanced with anti-radiation external black aluminum layer, a UV-resistant component making it more durable and suitable for exposed and open air piping installations even under direct sunlight.

With notable decreased linear expansion rate by 75%, and 20% increased higher flow rate. The exceptional anti-UV properties is tested and proven to be excellent in ultimate piping network performance for diverse applications.

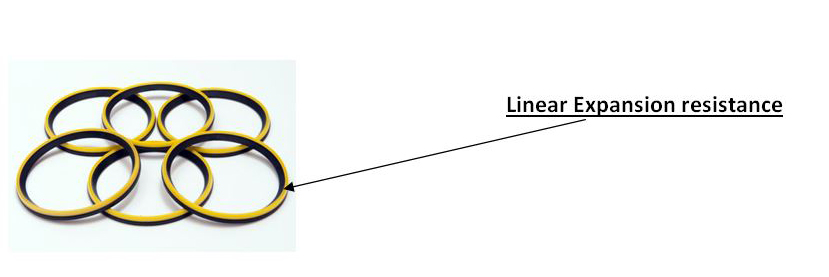

● RAKtherm Reinforced Fiber (RRF System)

One of the hindrances in using plastic material including PP-R pipes is the possibility to expand drastically when exposed to heat, we have developed RAKtherm Reinforced Fiber Pipes – a unique recipe of glass fiber layers; with innovative component of PPR and glass fiber in order to decrease linear expansion up to 70%. This makes the welding processes easier which requires lower supports, saving on installation time and effort.

● RAKtherm Reinforced Fiber with UV Protection (RRFV System)

A unique 4-layers pipe with glass fiber core layer and UV treatment skin outer layer for premium anti-UV protection. Mechanically stable being integrated with aluminum and external UV for maximum piping performance. 70% decrease linear expansion as compared to other pipes, and increased higher flow rate by 20%.

6. RAKduct Electric Conduit & Trunking System

RAKduct is a versatile and comprehensive electrical conduit and trunking system that is engineered for a higher level of precision performance and is used in all electrical wiring installations in modern residential, commercial, and industrial buildings. RAKduct always guarantees its customers the highest level of quality standards.

Backed by 6 decades of technical expertise, we are now elevating the technical performance of the traditional electrical tubings. Now, RAKduct is the versatile and comprehensive electrical conduit and trunking system that is engineered for higher level of precision performance, used in all electrical wiring installations in modern residential, commercial, and industrial buildings.

manufactured Technically for Higher Level of Efficiency

For the safety and durability, the kind and quality of the material you will choose to shield your electrical wiring system is crucial.

Those that are technically manufactured for higher level of efficiency to serve its’ purpose must considered; therefore, choose only RAkduct - the electrical conduit that is the most appropriate for such type of installation.

The Unparalleled Advantages of RAKduct System:

● Engineered for higher level of performance to meet stringent requirements.

● Resistance to compression.

● Highly durable.

● Long-service life.

● Light weight and easy installation.

● Adaptable to building structures

● Cost-effective.

Complete Range of UPVC Conduits. Trunks and Fittings

RAKduct consists of robust UPVC conduits and trunking systems that can handle corners, bends, and straight runs along with branchings. The basic cross-section is a round conduit, however there are alternative shapes that can be used to conceal exposed installations that will blend in with the interior as well as traditional hidden installations.

RAKduct Conduit and Trunking system is versatile and comprehensive, it can be used for electrical power, telecommunications, and computer data cable wirings. Sizes cover all your requirements inside the buildings.

Easy and Smart Installation Technique

RAKduct system is manufactured from uPVC materials, it can be easily cut, molded, bent, and linked in a number of ways. The installation doesn't require threading or specialized tools, which greatly improves efficiency. Due to its modest weight, manual handling challenges are also decreased. Therefore, it is cost-effective and time saving

RAKDUCT SYSTEM, A BEST CHOICE TO SHIELD YOUR ELECTRIC WIRING SYSTEM.

We believe that safety is a must; we never compromise the safety of our products. At RAKtherm, we produce products that are safe and harmless.

We always follow quality standards and policies of all products and processes implemented throughout the company through clear operating procedures, work instructions, forms, and records. This ensures that no aspect of the product is compromised and that all corporate and plant functions are defined and documented. This ensures that no aspect of the product is compromised and that all corporate and plant functions are meticulously defined and documented.

All operations follow the comprehensive quality system run and documented by RAKduct. In accordance with this, our production plant has received the ISO 9001 quality management system certification.

7. Fire-Resistant PPR Pipes

RAKtherm Fire Resistant PPR pipes exemplify advanced engineering, featuring a meticulous multilayered structure. The inner layer, precision-engineered crafted from premium PPR, is bolstered by a robust middle layer of glass fiber material. The outer layer is ingeniously formulated with PPR material infused with a specialized halogenated fire retardant. This intricate construction, characterized by the seamless integration of these high-quality materials, establishes RAKtherm as a benchmark for fire resistance and durability in the realm of piping solutions.

PRODUCT DESCRIPTION

RAKtherm Fire Resistant pipes are multilayered PPR pipes with the inner layer made of PPR, middle layer made of glass fiber material and outer layer made of PPR material mixed with special halogenated fire retardant material; Halogenated flame retardants intervene in the combustion reactions during the gas phase and form less reactive by-products, delaying or interrupting combustion. Halogenated flame retardants generally have the lowest usage rate. It provides a greater heat resistance, tensile strength, and durability features. These features can be effectively used in industries instead of metallic pipes.

Advantages of RAKtherm Fire Resistant Pipes:

● Reduce flame spread in FRP piping for direct fire exposure applications.

● Less weight, FRP will weigh one seventh as much as steel and half as much as aluminum.

● Excellent corrosion and abrasion resistance as well as overall durability.

● Low maintenance cost and easy installation.

● Lower thermal expansion.

● FRP pipes are excellent for chemical processing because of its corrosion resistance and chemically inert properties.

8. Gas Piping System

The Safest Gas Piping Solution

Unveiling RAKtherm Gas Piping Solution – Elevating Piping Excellence to Greater Peaks! Precision-engineered for robust performance in gas piping applications.

PRODUCT DESCRIPTION

RAKtherm presents Medium-density polyethylene (MDPE) and High-density polyethylene (HDPE) GAS pipes, meticulously engineered from specially formulated PE material, available in two distinct grades: PE80 (YELLOW) and PE100 (ORANGE). These grades are precisely determined by the long-term strength of the respective materials, referred to as the minimum required strength (MRS). The compound features a meticulously calibrated blend of pigments and optimized stabilizers, ensuring unparalleled long-term thermal stability and UV-resistance. This renders our pipes impeccably suited for deployment in natural gas distribution systems, and versatile enough to accommodate applications involving liquid petroleum gas (LPG), propane, and low-pressure after-meter gas.

Explore our comprehensive range of sizes, precisely tailored to meet diverse gas flow rate requirements, exemplifying our commitment to technical precision and professional excellence.

Tests As Per ISO Standard ISO 4437 & ISO 3126:

● Hydro static pressure test.

● Elongation break test.

● Resistance to slow and rapid crack.

● Thermal stability test.

● Melt flow rate.

● Longitudinal reversion test.

Advantages of RAKtherm PE Gas Pipes:

● Exceptional resistance to corrosion.

● Light and elastic structure.

● Long service life.

● Sustainable and eco-conscious product.

● Excellent resistance to rapid crack propa gation and slow crack growth.

● High strength structure.

● Low-cost maintenance.

● Quick and straightforward installation.

● Adaptive behavior with ground movements.

Physical Properties:

|

PE80 POLYETHYLENE |

PE100 POLYETHYLENE |

|

Density (Compound)-944kg/m |

Density (Compound)-951kg/m |

|

Melt Flow Rate (190°C/5.0kg)- 0.80g/10min |

Melt Flow Rate (190°C/5.0kg)- 0.25g/10min |

|

Tensile Modulus (1mm/min)- 800MPa |

Tensile Modulus (1mm/min)- 1000MPa |

|

Tensile Strain at Break (50mm/min) - >600% |

Tensile Strain at Break (50mm/ min)- >600% |

|

Tensile Stress at Yield (50mm/min) - 19MPa |

Tensile Stress at Yield (50mm/min) - 25MPa |

|

Pigment Dispersion-<=3 |

Pigment Dispersion-<=3 |

|

Oxidation Induction Time (210°C) - >=20mins |

Oxidation Induction Time (210°C) - >=20mins |

|

Resistance to Slow Crack Growth - >5000hrs (8bar 80°C) |

Resistance to Slow Crack Growth - >1000hrs (9.2bar, 80°C) |

AVAILABLE DIMENSION:

|

Nominal outside diameter dn |

Minimum wall thickness emina |

||||||

| SDR 9 | SDR 11b | SDR 13.6 | SDR 17b | SDR 17.6b | SDR 21 | SDR 26 | |

| 16 | 3.0 | 2.3d | - | - | - | - | - |

| 20 | 3.0 | 2.3d | - | - | - | - | - |

| 25 | 3.0 | 2.3d | 2.3d | - | - | - | - |

| 32 | 3.6 | 3.0 | 2.4d | 2.3d | 2.3d | - | - |

| 40 | 4.5 | 3.7 | 3.0 | 2.4d | 2.3d | 2.3d | - |

| 50 | 5.6 | 4.6 | 3.7 | 3.0 | 2.9d | 2.4d | 2.3d |

| 63 | 7.1 | 5.8 | 4.7 | 3.8 | 3.6 | 3.0 | 2.5d |

| 75 | 8.4 | 6.8 | 5.6 | 4.5 | 4.3 | 3.6 | 2.9d |

| 90 | 10.1 | 8.2 | 6.7 | 5.4 | 5.2 | 4.3 | 3.5 |

| 110 | 12.3 | 10.0 | 8.1 | 6.6 | 6.3 | 5.3 | 4.2 |

| 125 | 14.0 | 11.4 | 9.2 | 7.4 | 7.1 | 6.0 | 4.8 |

| 140 | 15.7 | 12.7 | 10.3 | 8.3 | 8.0 | 6.7 | 5.4 |

| 160 | 17.9 | 14.6 | 11.8 | 9.5 | 9.1 | 7.7 | 6.2 |

9. HDPE Piping System

Engineered for Excellence, RAKtherm HDPE pipes fortify infrastructure projects with enduring durability and superior performance:

RAKtherm’s HDPE piping solution is dedicated to delivering reliable and durable infrastructure solutions on a global scale. Drawing upon 60 years of experience in the petrochemical industry, we leverage our wealth of expertise to produce advanced piping technology. Through our commitment to sustainable development, we have consistently upheld the integrity of our distinctive infrastructure systems.

Elevating Infrastructure Standards in Critical Piping Applications

RAKtherm’s engineered infrastructure HDPE piping system efficiently conveys water from external sources, seamlessly transitioning from HDPE pipes outdoors to PPR pipes within homes, ensuring a reliable supply of both domestic hot and cold water. RAKtherm HDPE pipes are chosen for their exceptional durability, corrosion resistance, and versatility in handling external environmental conditions.

The Cornerstone of Modern Resilient Infrastructure:

Quality Engineering - at the core of RAKtherm’s superiority lies its commitment to precision engineering. Each HDPE pipe is meticulously engineered using advanced technological methodologies and adheres to the most stringent quality control measures. This precision ensures dimensional accuracy, consistency in wall thickness, and impeccable fusion joints, setting RAKtherm apart from its counterparts.

Redefining the Landscape of Infrastructure Piping System:

Material Innovation - RAKtherm’s HDPE piping utilizes the advancements in material science, employing high-quality HDPE compounds known for their exceptional strength, chemical resistance, and stress-crack resistance. This results in a piping system that is not only robust but also highly resilient to corrosive substances, ensuring longevity that exceeds industry norms.

Elevate your construction endeavors with RAKtherm HDPE pipes, setting a benchmark for durability and exceptional infrastructure integrity

Durability beyond compare, the enduring strength of RAKtherm’s HDPE piping highlights its engineering excellence. Engineered to withstand extreme temperatures, pressures, and environmental conditions, these pipes exhibit remarkable resilience over their operational lifespan. This longevity results in heightened operational efficiency for infrastructure piping system installations.